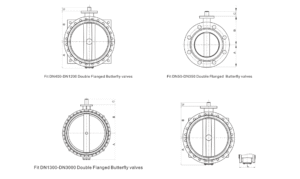

Double Flanged Butterfly Valve

The BLAZE™ BT 1425 Double Flanged Butterfly Valve is engineered for reliable performance in water, oil, and gas applications. Designed in accordance with BS 5155, it offers robust construction, excellent sealing, and long service life, making it ideal for high-performance flow control in municipal, industrial, and commercial systems. Its double flanged design allows easy installation between flanges in large pipeline systems, while the Fusion Bonded Epoxy (FBE) coating ensures superior corrosion resistance.

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 750 | 800 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN(inch) | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 28 | 30 | 32 |

| A | 80 | 80 | 95 | 114 | 114 | 139 | 175 | 203 | 242 | 250 | 317 | 341 | 367 | 432 | 488 | 517 | 544 |

| B | 110 | 134 | 131 | 150 | 170 | 180 | 210 | 245 | 276 | 328 | 376 | 407 | 433 | 508 | 560 | 610 | 620 |

| C | 30 | 30 | 30 | 30 | 30 | 30 | 34 | 34 | 34 | 40 | 52 | 52 | 64 | 70 | 95 | 95 | 95 |

| L | 108 | 112 | 114 | 127 | 140 | 140 | 152 | 165 | 178 | 190 | 216 | 222 | 229 | 267 | 292 | 305 | 318 |

| DN(mm) | 900 | 1000 | 1100 | 1200 | 1300 | 1350 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | - |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN(inch) | 36 | 40 | 44 | 48 | 52 | 54 | 56 | 60 | 64 | 72 | 80 | 88 | 96 | 104 | 112 | 120 | - |

| A | 615 | 669 | 753 | 794 | 968 | 1062 | 1066 | 950 | 1054 | 1164 | 1363 | 1445 | 1610 | 1795 | 1900 | 2040 | - |

| B | 692 | 735 | 813 | 917 | 990 | 1046 | 1000 | 1050 | 1150 | 1200 | 1360 | 1500 | 1650 | 1780 | 1900 | 2070 | - |

| C | 130 | 130 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 300 | 300 | 300 | 300 | 350 | - |

| L | 330 | 410 | 450 | 470 | 490 | 490 | 530 | 570 | 600 | 670 | 760 | 636/800 | 850 | 900 | 950 | 1000 | - |

- Municipal water supply and distribution

- Wastewater treatment plants

- Oil and gas pipelines

- HVAC and cooling water systems

- Power plants and industrial fluid handling

- Irrigation networks

- Marine and offshore installations

Description

- Heavy-Duty Design – Double flanged for secure mounting in large pipelines.

- High Corrosion Resistance – Internal and external Fusion Bonded Epoxy (FBE) coating.

- Versatile Sealing Options – EPDM or NBR seat for various temperature and media requirements.

- Leak-Tight Performance – Complies with BS 5155 for assured sealing.

- Wide Pressure Range – Suitable for both 16 bar and 25 bar systems.

- Ease of Maintenance – Replaceable seat design.

- Multiple Standards Compatibility – Available in PN16 and ANSI flange drilling

Additional information

| Design Standard | BS 5155 |

|---|---|

| Working Pressure | 16 Bar / 25 Bar |

| Flange Options | PN16, ANSI |

| Coating | Internal & External Blue (RAL 5015), FBE Coating |

| Body Type | Double Flanged |

| Model Number | BT 1425 |

| Size Range | 2" to 120" (50 mm to 3000 mm) |

| Seat | 17.6 bar / 27.5 bar |

| Medium | Water, Oil & Gas |

| Testing Pressure Shell | 24 bar/37.5 bar |

| Working Temperature EPDM Seat | -20°C to 110°C |

| NBR Seat | -10°C to 80°C |